-

Mobile Version

Scan with Mobile

- Member Center

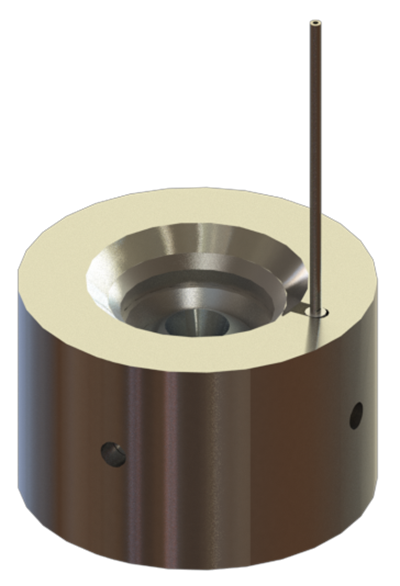

Cm / C diamond anvil cell

This kind of cell is widely used in the research of low-temperature non-magnetic high-voltage science, which can meet the needs of axial and radial light, and can cooperate with low-temperature devices for optical, X-ray, electrical and synchrotron radiation experiments.

Technical description of CM cell:

1. The material is imported high strength beryllium copper with hardness of hrc41 after heat treatment ± 1;

2. The pressure chamber made of v350 material is type C, which can be used for higher strength pressure test;

3. The processing specification is based on the metric specification, equipped with imported metric screw accessories;

4. Machining accuracy requirements: parallelism is better than ± 005, no tolerance indicated ± 0.02, coaxiality 0.003, perpendicularity 0.002, finish - base surface 0.4, end face 0.8; WC seat, 0.005 parallelism, no tolerance ± 0.02, hardness hrc90;

5. Appearance Matt antirust treatment, independent vacuum packaging;

Each set of press accessories: beryllium copper grade m3 * 20 left and right screw, 2 for each; There are 8 m1.2 top wire base meters, 8 beryllium copper labyrinth disc springs and 1 protective base meter

Anvil support material: tungsten carbide;

Pressurization mechanism: bolt disc spring pressurization

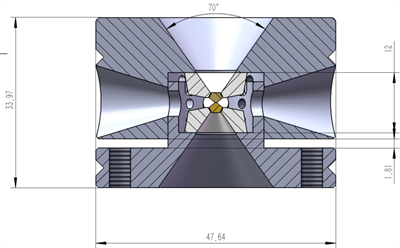

Top opening angle: 30 degrees; Bottom opening angle: 34 degrees

DAC height: 29.58mm

DAC outer diameter: 20.32mm

Working distance: < 15mm

Center height: 7.62mm; Center aperture: 2.0 mm.