-

Mobile Version

Scan with Mobile

- Member Center

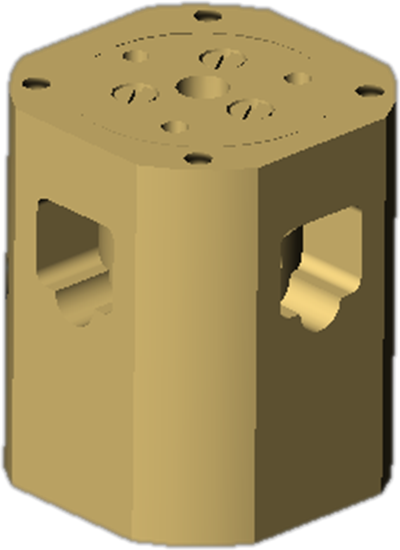

PPMS-20.5 DAC

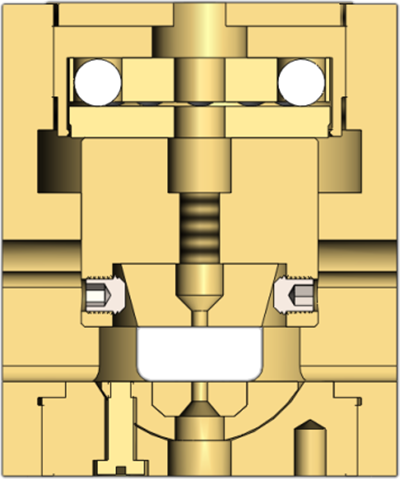

This kind of cell is widely used in high-strength and high-voltage magnetic scientific research, which can meet the needs of axial and radial leads, and can cooperate with cryogenic devices to carry out corresponding experiments of magnetism, electricity, X-ray, electricity and synchrotron radiation.

Technical description of ppms-20.5 cavity:

1. The material is high strength non-magnetic beryllium copper;

2. The yield strength of the material is more than 1400MPa, and the hardness after treatment is hrc41 ± 1;

3. The processing specification is based on metric specification, equipped with imported metric non-magnetic beryllium copper screw accessories;

4. Machining accuracy requirements: parallelism is better than ± 005, no tolerance indicated ± 0.02, coaxiality 0.003, perpendicularity 0.002, finish - base surface 0.4, end face 0.8; NiCrAl seat, 0.005 parallelism, no tolerance ± 0.02, hardness HRC60;

5. Appearance Matt antirust treatment, independent vacuum packaging;

6. Each set of press accessories: beryllium copper grade m3 * 20 left and right screw, 2 for each; There are 8 m1.2 top wire base meters, 8 m3 disc springs, 1 protective base meter and 2 WC cushion blocks;

7. The warranty is 1 year.

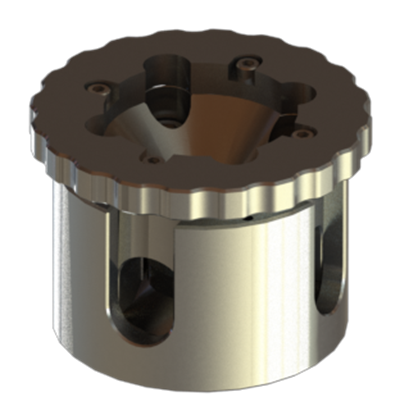

Anvil support material: NiCrAl alloy;

Pressurization mechanism: bolt disc spring pressurization

Top opening angle: 30 degrees;

Bottom opening angle: 34 degrees

DAC height: 32mm

DAC outer diameter: 20.5mm

Working distance: < 15mm.